Heat Safety Training This Summer Can Keep Employees Safe

Corey Bleich

🍿 5 min. read

Workers are at increased risk for heat-related illnesses when the mercury rises in summertime.

Filled with long days and ample sunshine, summertime vacations at the beach and family picnics can be some of the best times of the year. On the other hand, workers in many industries are at increased risk for heat-related illnesses—and even death—when the mercury rises. Heat safety training can help. Here's how to design training to protect your employees.

What is heat safety training?

You may think that heat safety training is just for construction workers working outside in the heat of summer, but it’s much more than that. Firefighters, bakery workers, farmers, miners, boiler room workers, factory workers, and more all need heat safety training to stay safe on the job year-round.

Further, rising global temperatures may contribute to an increase in heat-related illnesses and deaths. In 2018, 60 workers in the U.S. died on the job due to heat stress. And, while the Occupational Health and Safety Office (OSHA) keeps track of reported heat accident statistics, these do not include unreported statistics for small businesses and sole proprietors. Heat and heat-related illness is one of the deadliest (and most preventable) weather-related health issues in the U.S.

So, what is heat safety training and how can it help?

Heat safety training focuses on helping workers learn how to recognize the signs of heat stress and also to prevent it. More than just an update on new systems or regulations, heat safety training might save your employees’ lives.

How do you stay safe working in the heat?

Staying safe in the heat takes a multi-pronged approach that start before the workday even begins. Your heat safety training should cover the following safety guidelines.

Assess heat conditions

There are some conditions under which employees should not work at all. High heat, when combined with high humidity and low air circulation, can be fatal. Consider not only workers out in the sun, but also those who work in places where such conditions exist (e.g., attics and closed factories).

Workers under these conditions will need to understand how at-risk they are. The Personal Risk Factors Self-assessment Questionnaire (English or Spanish) can help them and their managers evaluate this and take proper safety steps. For jobs that must be done no matter what, taking plenty of breaks to rest in the shade or get fresh air can help them stay safe.

Ease workers into their day

If you have workers who are new to a high-heat job, consider adding them at part-time status to allow them to acclimatize. You might also consider having them work in the early morning hours or after 5 p.m., out of the hottest parts of the day.

Dress for safety

Light cotton layers keep the body cooler than shorts and a tank top. Light colors also reflect heat away from the body.

Broad-brimmed hats can help keep the sun off of workers’ heads and shoulders, too.

Hydrate

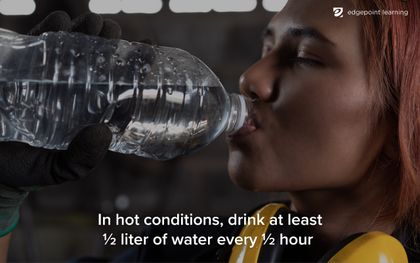

Drinking enough fluids—water and other liquids with electrolytes—is key to staying healthy.

When heat hazards like high temps, high humidity, and poor air circulation are present, you are dehydrating faster than you think. Workers should drink even if they don’t feel thirsty following the half-and-half rule: drink ½ liter of water every ½ hour.

Which topics should I cover in our heat safety training?

Heat safety training includes both prevention of heat stress and responding to employees who are in potential danger.

Your training topics might include:

- The major types of heat illness, from heat cramps to heat stroke

- How to recognize the signs of illness

- Additional risk factors, like medication usage

- Treatment protocols for each stage of illness

- Heat illness prevention training, for managers and employees

Each training and the topics covered will be different and tailored to your workforce's needs. You can read more about other safety training topics to cover here.

How to design heat safety training

The best heat safety training programs send workers well-prepared out into the field. Designing a good one takes a few steps.

1. Assess your starting point

Designing a heat safety training starts by first evaluating what you are doing well and what needs tweaking. For example, if your workers know how to recognize heat stress, then your program might focus on heat-related illness prevention and treatment.

An assessment also includes looking at which employees are most at risk for heat stress, figuring out a timeframe for delivering training to these high-risk employees, and then assessing your program's effectiveness.

Further, inventorying your current resources takes into account all of the information, hardware, people, and training that you already have on board. This helps avoid redundancy and saves you and your employees time and money.

For details on how to conduct a full training needs assessment, check out our post here.

2. Develop a checklist for safety

Developing a mobile checklist—like the ones offered through PinPoint Workforce—allows you to deliver training in the flow of work using an app on a smart phone. Checklists for heat safety can include a push notification for necessary breaks, questionnaires about symptoms or water consumption throughout the day, and a personal inventory of safety gear.

Checklists can also function as on-demand training for a task. For example, for technicians entering a hot attic to perform an installation, keeping all the steps of the installation handy can make their work more efficient and minimize time spent in a heat hazard.

The best part about mobile checklists is that they give employees a clear guideline to follow, no matter where they are.

3. Design your training

OSHA’s heat safety guide offers an excellent framework to work from. As you design your training, adapt their information to the training tools you choose for your employees.

Consider microlearning in the flow of work as a way to get information to employees without pulling them out of their day. This can be anything from alerts to extreme temperature changes, updates to guidelines on a jobsite, or reminders to take breaks at certain times—all delivered via their mobile device.

Other options may include short informational videos, scenario-based lessons for illness prevention, or robust courses for site managers.

Build your heat safety training program

Developing a new heat safety training program can be difficult, but it's crucial to protecting your workforce's safety. And, EdgePoint Learning can help.

We can design custom training from the ground up, or help you incorporate one of PinPoint’s prebuilt mobile courses to your existing course material. Need to roll out training quickly or with limited resources? We also offer co-development services, and act as an extension of your team to help with instructional design, graphics, animations, voiceover talent, and overall development.

If you're ready to get started on your heat safety training, get in touch. As a Phoenix-based company, we understand the very real risks of heat illnesses. We can help you create an accessible course that keeps your employees safe this summer.